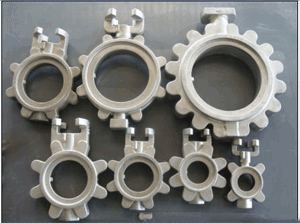

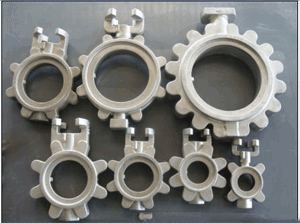

Production and Mold

• Disa Molding 20” x 25” and 21”x 20”

• Squeezing Floor Molding for Size Up to 14” x 20”

• Shock Squeezing Molding for Size to 25” x 25”

• Hunter Molding for Size Up to 20” x 30”

• Cope & Drag for Size Up to 30” x 50”

• Loose Pattern for Size Up to 50” x 70”

Molding Media and Core/Pattern

• Core-making Machines for Complex Highly Cored Casting

• No-Bake Sand for Casting with Excellent Surface Quality

• Shell Sand for Casting with Superior Finish and Near Net Shape

• Green Sand for Casting with Less Critical Surface or Tolerances

• Steel, Aluminum, Wood and Plastic Pattern

Secondary Operation

• In-house Annealing and Heat Treatment

• CNC Machining, Turning, Milling, Drilling, Tapping and Grinding

• Blast and Vibratory Cleaning, Electroplating and Powder Paint

• Assembly